Kidde IND Industrial Fire Suppression Systems

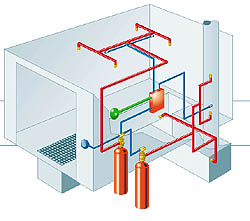

Kidde IND™ Dry Chemical Fire Suppression Systems

Maximum Fire-Killing Power for Industrial Applications

Three Choices of Fire Detection

Three Choices of Fire Detection

Depending upon your hazard, one of three Kidde detection methods will best suit your needs. Mechanical detection uses fusible link detectors to provide reliable performance at low cost. Electric detection offers enhanced sensitivity and the design versatility of thermal, smoke or optical detectors for compatibility with just about any type of hazard environment. Pneumatic detection combines high sensitivity with no-spark operation necessary for explosion-sensitive applications or where electrical power for system operation is not available.

Single or Multiple System Control

Single or Multiple System Control

If you have one hazard area to protect, the Kidde SCORPIO™ Control Panel gives you microprocessor-based reliability in a fully supervised suppression release and alarm output system. If you’re controlling multiple Kidde fire alarm or suppression systems, the smart choice is the Kidde PEGAsys™ Control System, our latest detection technology that uses a “distributed intelligence” concept to of more detection and alarm capability, faster response time, more immunity to nuisance alarms and lower maintenance costs.

The Right Cylinder Sizes

The Right Cylinder Sizes

Your Kidde Distributor can choose from three sizes of agent storage cylinders using ABC or BC dry chemical – Kidde IND 21 (ABC)/25 (BC), Kidde IND 45 (ABC)/50 (BC) or Kidde 70 (ABC)/75 (BC) – to design the precise system that best meets your fire protection requirements while conserving hardware and dry chemical agent cost.

Superior Coverage

Superior Coverage

Due to our advanced nozzle design, Kidde IND Systems cover more volume of hazard area with less dry chemical agent than any other brand of total flooding system. Dry chemical is discharged both radially and downward to maximize coverage. What this means is that we can protect your application using a minimum number of agent storage cylinders. Less hardware means a lower installed cost.

Listed and Approved

Kidde IND Systems, with ABC or BC dry chemical agents, are listed by Underwriters Laboratories, Inc., Underwriters Laboratories Canada and approved by Factory Mutual for operating in temperature ranges from -40°F to 120°F.

Rugged Kidde IND™ Systems Are Recommended For All Types of Industrial Fire Protection:

Processes Involving Flammable Liquids

- Quench Tanks

- Industrial/Automotive Paint Spray Booths

- Coating Operations

- Dip Tanks

Electrical/Mechanical Rooms

- Boiler Rooms

- Switchgear Rooms

- Generator Rooms

- Furnace Rooms

Flammable Liquid Storage Areas

- Flammable Liquid Storage

- Paint Mixing Areas

- Spill Containment Dikes

- Bulk Storage

Specialty Hazards

- Modular HazMat Storage Facilities

- Exhaust Ducts

- Environmental Storage Facilities

- Machinery Spaces